August 15, 2013

Daystar Filters announces upgraded capacities:

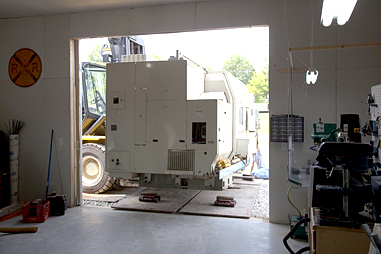

DayStar received delivery of upgraded machining equipment capable of higher precision and production fabrication in house.

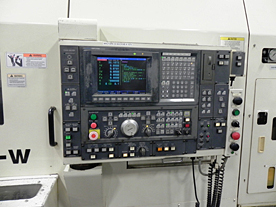

Always striving for higher precision and improved quality, DayStar has recently upgraded their facilities and acquired new precision machining equipment. The newly added Okuma Mac Turn 30-w 7 axis CNC lathe center is designed for ultra-high quality and higher in-house production.

Following the business principle of vertical integration made popular by such successful business models as Space-X and other niche fabrication companies. Bringing more production capacities in-house reduces cost, improves quality and production time. Innovations and revisions take less time to bring to production, and manufacturing standards can be maintained throughout the fabrication process.

DayStar has always been proudly MADE IN USA. This new purchase assures the company always will be able to maintain this quality standard.

Delivery was made to the recently expanded 4500 square foot DayStar production facility at the ICSTARS Ranch in Warrensburg, MO. New facilities added house a larger coating facility, assembly area and an expanded electronics design, test and fabrication department. “Today marks a new beginning for DayStar. Now the real work can begin. ” Jen Winter, Aug 2013

2025 Update: DayStar’s machine shop has grown over the years and now comprises this Okuma, two twin spindle / twin turret CNC lathes, a vertical CNC mill, and a Mori Seiki horizonal mill with pallet changer.